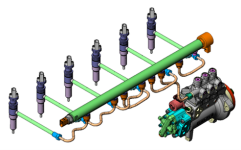

DME Injector is a bespoke design for DME operation. Injector architecture incorporates isolation valves to ensure low internal leakage. Valve technology was developed for increased durability when operating with DME and optimised for the low lubricity fuel characteristics. Rubber seal material compatibility with DME fuel was another important area of focus undertaken in the project.

DME pump runs at 300bar pressure and is based on the Delphi HD common rail pump used for Diesel operation (runs up to 2400bar). DME pump uses existing parts / technologies where possible and has been uprated to match the fuel flow demand.